At the risk of talking down to some readers and over the head of others I feel the need to explain the term “bottom bracket”. According to Sheldon Brown’s Bicycle Glossary a bottom bracket is:

The part of the frame around which the pedal cranks revolve, also the bearings and axle assembly that runs through the bottom bracket shell of the frame.

Looking at the late Mr. Brown’s page I realized I am opening a bona fide can of worms. There are several bottom bracket “standards”, and bottom bracket/crankset interfaces. We won’t even get into “outboard bearing” and “BB30” and other new standards which are mostly calculated to keep the buying public buying, while claiming to add some performance advantage…not performance related to the durability or function of the piece… but of the rider/bike.

“Square taper” bottom brackets are made to work with “square taper” cranksets and cranksets with suitable chain ring sizes for touring generally are of the square taper variety. Clink this link for a discussion of gears and gearing. So this series of pieces will be about square taper bottom brackets.There are still compatibility issues to think about though. The taper on Italian (Campagnolo) cranks and bottom brackets are different from the taper on cranks and bottom brackets made anyplace else in the known Universe, which actually is typical of Campy parts. And bottom brackets come with different spindle lengths. The correct spindle length for a given bicycle will be a function of the width of the bottom bracket shell, the shape of the chain stays and of the shape of the crank. For example: with a Sugino XD500 (XD2) triple crank set on a Surly Long Haul Trucker, a 107mm to 110mm spindle length works well.

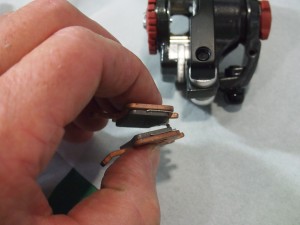

Before the widespread use of cartridge bearings, bottom brackets were designed with loose balls or caged balls running on races inside the cups and races shaped into the spindle. Mechanical seals or o-rings were used to keep out water and dirt. Nowadays the spindle is held inside a case by means of sealed cartridge bearings pressed onto the spindle. The only seals being those on the bearings themselves. A less than ideal state of affairs for the part of the bicycle in a location that will be sprayed from time to time with a slurry of water, grease, oil, de-icer, sand and grit.

So, what’s the dyed-in-the-wool bike tourist to do? In the following posts we will explore some of the available options for touring bike bottom brackets. If the idea of reading about that titillates you, you should think about getting a life.