Back in December 2017, Surly announced the release of a new front-loading light touring bike – the Pack Rat. I was excited about the possibilities from the moment I learned of this bike’s existence and Bike Touring News was one of the first shops to stock them. In the intervening 4 months, Surly has released no fewer than three more new models – the “Allroad” Midnight Special, a redesign of the Pugsley expedition fatbike and the entry-level dirt touring Bridge Club.

What with all this newness in such a short period, I was a little afraid that the humble Pack Rat might be forgotten. I had already had favorable impressions from brief rides around town, so I set out to test this bike’s capabilities on a weekend ride. I wanted to know if the Pack Rat was capable of loaded touring over the mix of terrain we commonly encounter here in Idaho and if this was a platform I could recommend for two-wheeled exploration past the end of the pavement.

In order for this road test to be meaningful, I’m going to need you to hang with me in the Land of Make-Believe for just a little while. Got your Imagination Cap on? Good.

I’m going to make a statement that should be treated as fact for the duration of this post. Ready?

The bike pictured below is a Pack Rat. Got it?

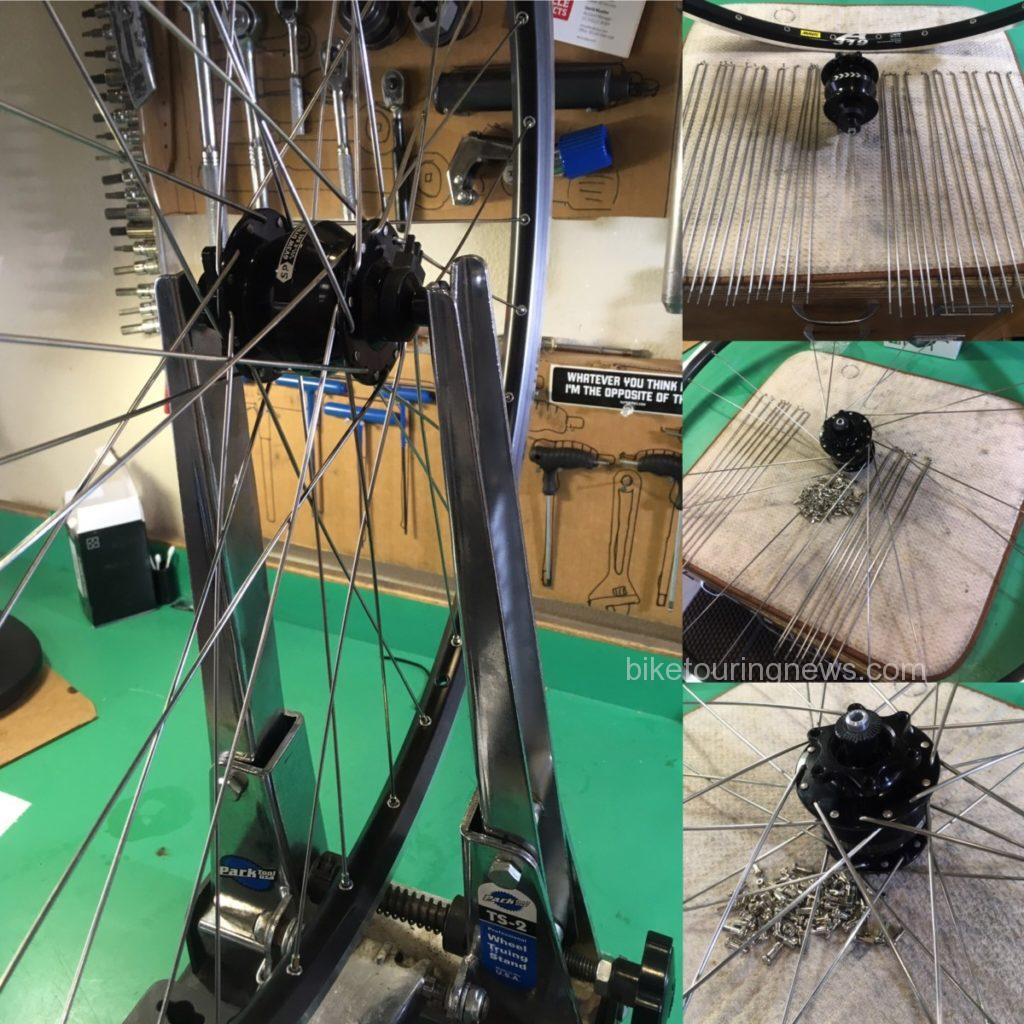

My old war horse of a touring bike – affectionately known as the Rando-Gnar – is nearly identical to the Pack Rat in every way that matters. Both bikes are designed around 650b wheels with clearance for 47mm “Road Plus” tires. Both feature geometry optimized for a front load. Steel frames, drop bars, cantilever brakes, plenty of braze-ons for racks and cages. Heck, they’re even (almost) the same color. Nearly every component on the Rando-Gnar would move right over onto a Pack Rat frame.

In order to transform a stock Pack Rat into the bike you see above, all you need to do is mount a set of WTB Byway tires, drop the gearing down a bit and attach whatever racks and bags you deem necessary. Boom, pow! You’re ready to pack your gear and hit the road.

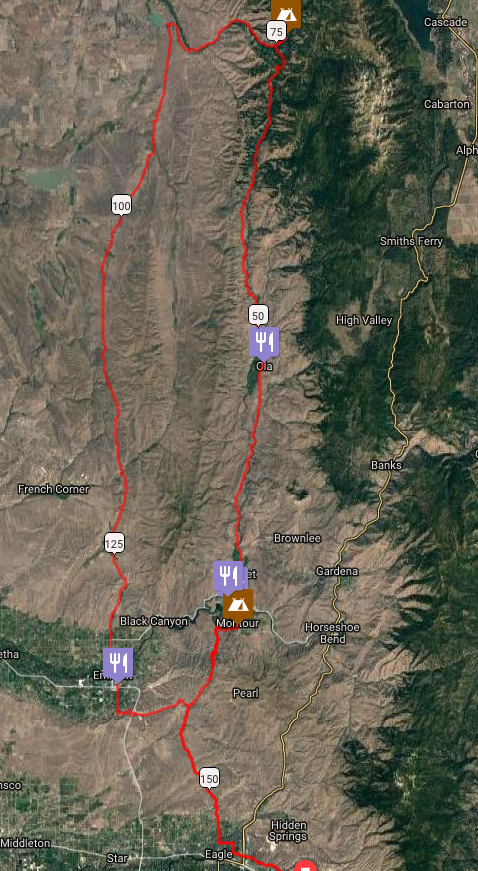

For this exploration of the Pack Rat’s touring capabilities, I mapped out a route that would cover around 160 miles of paved and dirt roads that would vary widely in condition. I knew of one stretch of unmaintained road that would likely be in very poor condition. The roads that climbed into the foothills of the Boise and Payette National Forests were more of an unknown quantity as I had not ridden them before. I had some idea of what to expect and had been assured by a Forest Service Ranger that the roads were free of snow – though I had my doubts. Most of the remainder consisted of varying qualities of pavement and maintained dirt roads.

I set out from Boise on smooth pavement and re-adjusted to the ride of a loaded bike. My haphazard packing strategy resulted in a heavier bike than I would have liked but I felt confident that I was well prepared for the unpredictable springtime weather and road conditions. Rolling tubeless at 42psi, the Byways cruised down the pavement nearly as fast as a good racing tire. I felt the weight of my load when the road turned uphill but the ride was speedy and efficient overall.

When the road turned to dirt in the rolling foothills north of Eagle, the Pack Rat pressed ahead with aplomb. Traction was adequate for out-of-the-saddle riding over some of the steeper pitches, though I had to be conscious of my weight distribution to prevent the rear tire from slipping on looser ground.

From the saddle at the top of Sand Hollow Road, our route descended the unmaintained Johnson Creek Road to the Payette River. This road bears deep, rutted scars from heavy truck use in wet conditions and is very eroded in spots. We rolled in, enjoying the views while keeping to the high ground between the ruts.

The ruts were nearly three feet deep in spots but the clay was hard and firmly packed, making for predictable traction even at off-camber angles.

One section of the road has been completely taken over by the creek and presents about a quarter-mile of bumpy riding over loose, slippery river rocks. I rode cautiously but never felt in danger of bottoming out my tires.

Johnson Creek Road drops into Shalerock Road, a wide and well-maintained dirt road that descends into the Montour Valley. We basked in the dusky light on the descent to the Montour Campground for the first night’s camp.

After a hearty breakfast at the Triangle Cafe we struck out to the north the next morning, gradually gaining elevation on the paved Sweet/Ola highway. The snowy mountaintops in the distance made me wonder about the elevation of the snow line.

The road turns to dirt a couple of miles past the little town of Ola. Conditions were excellent – nicely packed clay with a scattering of loose pea to marble-sized gravel. The Pack Rat carried speed well and cornered confidently.

I was forced to adapt my pedaling rhythm to the lumpy terrain and the Pack Rat responded well – forging forward to crest each roller as I rose out of the saddle.

The Byway tires provided a sufficiently large contact patch and plenty of cushioning to keep the bike composed on the quick descents. Momentum is everything when pedaling a loaded bike, so it was nice to have the confidence to let the bike run on the short downhills and carry good speed into the next climb.

The road continued to wind its way north, following Squaw Creek toward its headwaters in the Payette National Forest. We were getting close to 4,000 feet above sea level and entering the pine forest, so we began to encounter wet conditions and sections of slushy snow on the road.

The 47mm tires sank somewhat into the softened road surface, slowing their roll and forcing me to work harder for the same speed. However, they certainly provided more traction and flotation than narrower tires would have.

The road began to climb more steeply and the snowy stretches became longer until they became practically uninterrupted.

While the snow was not very deep, the Byway’s diamond tread didn’t provide enough bite for steering or pedaling through the slippery slush. Likewise, the 47mm width was not sufficient to say on top of the crust layer. I could ride brief stretches when the road leveled out but climbing was not possible.

When I was able to ride, I was constantly attempting to correct my line and keep the bike from sliding out from under me. A mountain bike with 2-3″ tires would have handled these conditions much better than the Pack Rat but would have also been sluggish on the pavement and smooth dirt roads.

We pressed on despite the snow-covered road. Traction was sufficient for walking and I didn’t think the pass was all that distant. In hindsight, I probably should have paid attention to the omens and turned back.

The snow continued to get deeper until it dragged at the bottom of my panniers. The north-facing section of road just over the summit held drifts at least 3 feet deep. I’m sure this road will be spectacular in a couple of months when all the snow is gone! I don’t know how long it took to cover the 8 or 9 snowy miles but the time would definitely be measured in hours.

Clearly, these conditions were well outside the Pack Rat’s intended use. Even a fatbike with 5″ tires would have been useless in snow that deep and wet. I could have certainly saved myself some pain and suffering by turning back but I had made good time earlier in the day and knew I had sufficient daylight to get through. I pushed, dragged, slipped and postholed over and down the pass, hoping that my planned campsite wouldn’t be under snow.

The campground still held some snow but there was plenty of dry ground. I breathed a sigh of relief to have arrived and then set about drying my shoes and feet, eating food and doing my best to recover for tomorrow’s 90+ mile burn back to Boise.

I slept deeply and woke feeling surprisingly fresh after the previous day’s exertions. I made breakfast, pulled on my frozen shoes and hit the road just as the sun began to peek over the eastern ridge. The forest service road had yet to shake off the night’s chill. Yesterday’s soft, wet mud and slippery slush had hardened into frozen dirt and roughly textured ice. The Pack Rat excelled in these conditions, though I rode the icy sections cautiously and did walk a couple of slicker stretches.

Before long, the road reemerged from the trees and dried completely. Conditions on the southbound leg started off similar to the northbound side. The cloud-filtered sun warmed the air and I enjoyed the (mostly) downhill grades and undulating terrain. The Pack Rat hummed along, carrying speed through the troughs and over the top of the endless rollers.

When we hit the Washington County line road conditions changed drastically. The road had recently been graded and was evenly surfaced with 1-2″ size gravel. I’d estimate the gravel had been laid no more than a week prior. There were decent tracks laid down by auto traffic through most stretches but the rock lay in piles several inches deep in some spots. Line choice was key, but the Pack Rat handled these challenging conditions admirably. I’ve often felt that slimmer tires perform well in these kinds of conditions as they are narrow enough to push the loose rocks aside and grip on the hardpack beneath where a wider tire would float and roll on the top layer.

After turning off the recently-graded stretch of road conditions improved. There were some seriously steep climbs on this leg of the ride that I would have wished away but the Pack Rat never held me back. My legs had begun to tire and struggled to supply the necessary power.

Approaching the town of Emmett, it began to look like the highway would be a better option than returning via yet more nasty rollers in the Eagle foothills. My body was tired and shadows were getting long. We spun our way down the paved highway shoulder into the valley, turned to the east and finished the final few miles back to Boise. My pedal strokes were weak and I was happy to be on a bike that rolled efficiently and didn’t ask for much leg strength to maintain forward progress on the asphalt and chipseal.

Overall, I came away from this ride even more excited for the Pack Rat’s potential. It may not be your go-anywhere touring bike. There are plenty of roads, tracks and trails over seriously rugged terrain in Idaho where a little more bike (Ogre, Troll, ECR, Bridge Club, etc.) would be a better fit. It also won’t carry a transcontinental load as well as the Long Haul or Disc Trucker. However, if you want a bike to travel a mix of dirt and pavement with a light-to-medium load on the weekend, pull double-duty on the weekday commute and have a good time doing it, the Pack Rat is worth your attention. If nothing else, it’ll get you out of town and into the fun stuff in a hurry!