A Tale of Chain Suck

By replacing my chain and the middle ring on my triple Sugino touring crankset I thought my problems would be solved. The chain would now drop smoothly from the middle ring to the small ring without hanging up on the bottom of the middle ring, getting dragged around and over the top and getting jammed or “sucked” into the front derailleur. For the technical minded, this article about chain suck is informative. Basically, worn chain rings and/or a worn, dirty chain will contribute to chain suck. But, even with the new chain and middle ring the chain still was reluctant to disengage from the bottom of the middle ring when I wanted to shift to the smaller ring.

I have never been entirely happy with this crankset for a couple of other reasons:

1.) the arms are 175 millimeters long when I would have preferred 172.5

2.) the Q-Factor has always felt too wide to me.

3.) there are several combinations of chainring/rear cog that are either unusable or redundant.

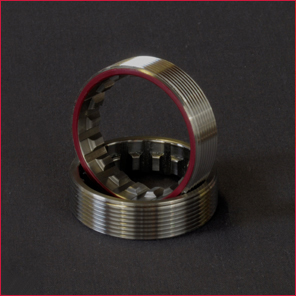

The mountain biking world has been addressing the inefficiencies of triple cranksets and now so-called 2x and 1x systems using either two chainrings or just one with 10 or 11 speed, wide-range rear cassettes proliferate. When I saw the new “wide compact road double” crankset from Interloc Racing Design (IRD) I decided to take off the curmudgeon hat and put on the practical hat.

I had to consider a number of things in making the swap;

-First, I obviously want a decent range of gears suitable for a loaded touring bike. I used the Sheldon Gear Calculator as I describe in this blog post and see that a 10 speed cassette with a small cog of 11 teeth and a big cog with 34 teeth will give me the same high end as I have with the triple and a slightly easier low gear, which is a bit of a bonus, and will give me a few more usable gears (less cross-chaining) and fewer redundant gears.

-Second, my front and rear derailleurs need to be able to deal with new rings and cogs and with a ten speed chain. The front triple derailleur, while it does not have the ideal shape for the compact rings moves the chain back and forth quite smoothly. I use a friction downtube shift lever so the 9 speed derailleur works with the narrower 10 speed chain but a 9 speed front derailleur will generally not work with an indexed shifting system made for ten speed. The rear derailleur can handle the chain wrap because there will actually be less chain to tension than with the triple setup. The medium cage Ultegra derailleur has a nominal large cog maximum of 30 teeth though, four teeth smaller than the 34 I am using. When in the big cog I am unable to adjust the derailleur to keep the upper pulley far enough away from the bottom of the cog but if that proves to be a problem, I can get a different derailleur.

-Third, since I still like an indexed rear shifter I need 10 speed downtube levers. And of course I will need a new, 10 speed cassette and chain.

– My fourth consideration was Q-Factor. IRD recommend a JIS square taper bottom bracket with a 118mm spindle length to achieve the best chainline and, using that suggestion I ended up with an almost perfect chainline. The Q-Factor is now 1 centimeter narrower which I’m hoping will be more comfortable and efficient.

I feel like simpler is almost always better and I like the simple, clean look of this setup. The IRD crankset has a jewellry-like finish and a muscular appearance, which might be even a little more traditional looking than the Sugino. The real test of the success of the conversion will be taking longer rides and going touring with it.