The temperature is going to be well below freezing this New Year’s Eve day and several inches of snow have fallen in the last 48 hours. A combination of de-icer, sand spread by the highway district and traffic has left the busiest roads mostly bare and dry. But driveways and side streets are covered with (one after another, or all at the same time) patches of snow, ice, slush and gravel. I’m not riding the bike today.

This morning I looked in a supplier’s catalog at tires with 400 or so carbide steel studs in the tread. I’m tempted to buy a pair but I’m not sure if even that would keep me upright on the ice. And the use for such tires is limited…I don’t really want to be taking them off and putting them back on every time it snows. If I had a bike with disc brakes I could try the old zip-tie snow chain trick.

Earlier this month, before the snow was sticking, we went on a day trip from Three Horse Winery north of Eagle, ID to Montour, ID where we ate lunch before riding back. Scott and Aileen scouted this route prior and they were going to show us the fabled passage between Eagle and Montour which we had been unable to discover on our overnight trip last year. This turned into sort of an epic slog through mud and water and emphasized the importance of the right bike for the job… those of us with fenders spent quite a bit of time digging packed mud from between the tires and fenders. We even ended up taking Sky King’s front fender off when her front wheel completely bound up and stopped turning. For those on bikes without fenders and using disc brakes the going was relatively easier.

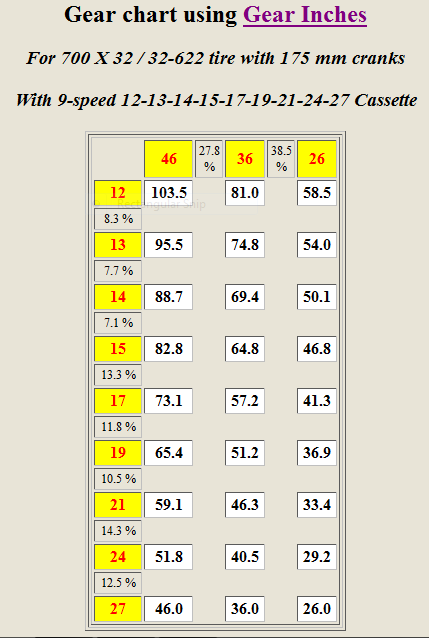

Here is a map of the route for those who might want to repeat it.

Even with the mud everybody had a great time and there was more smiling taking place than cursing although there was some of both. That is partly a testament to the cohesiveness and the great attitude of our fledgling bike touring group wherein everybody is quick to help others and nobody complains. Plus, every rider is competent and able to take care of themselves on and off the bike.

A touring bike continues to open my eyes to the scenic and solitary places within an hour or two of where we live. Places I never visited in the previous two decades of living here and probably would not have experienced in another 20 years, but which are suddenly accessible on my country bike. Not to mention a new group of friends….a group of thinking, entertaining and interesting people who make this hermit happy to be a part of it.